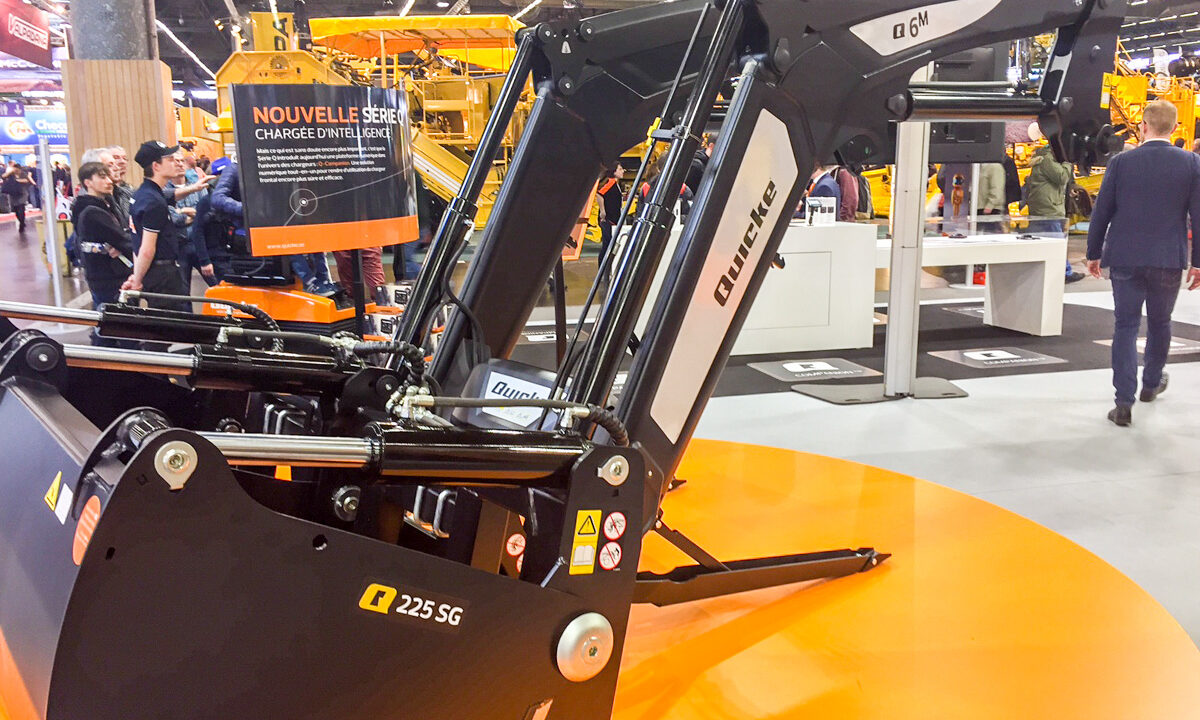

Alo AB showcased its latest line of Quicke front loaders – the Q Series – at last week’s SIMA show in Paris.

The Q Series front loaders, along with Q companion, were unveiled to the public for the first time.

The Q Series has been developed to become the flagship front loader for Alo AB and, according to the company, it provides “smart technological solutions”.

Some of the features of the Q Series include forged rear-arm parts and cast knee and front components, which are said to lend it “extra strength and durability”.

In addition, the company says that its Delta sub-frame system has “extraordinarily heavy-duty dimensions” with many “precision-machined surfaces” – such as the 60mm-wide U-support and 40mm locking pin.

Visibility is the key

Improved visibility is also a key draw of the Q Series, according to Alo AB. The company says that the design of the loader’s cross-tube and knees gives “a better view from the driver’s seat than ever before”.

Alo AB says that there are no pipes or hoses to distract or limit your view, as they are protected “well within the loader’s arms”.

Also, the Q Series comes equipped with “fully integrated smart sensors that monitor the operator’s every move”.

The development of the Q Level feature, says Alo AB, allows operators to quickly crowd the bucket to an angle of 58%, at a height ranging from 0.65-0.85m.

This is said to result in “less spillage over the front or back of the bucket”.

Weigh and record on a USB memory stick

Q Series loaders can be fitted with Q-Companion – a digital screen and smart-sensor system that allows the loader operator to “weigh as you lift”.

This device does away with the need of having to move to a separate weighing station to the weigh the contents of the bucket.

Alo AB claims that the weighing feature has been developed and tested specifically for routine farming jobs, such as scooping, bale handling, silage handling and pallet handling.

The device, says the company, can be calibrated for up to 10 different implements. Q-Companion also lets you export your data on an included USB memory stick for “administration or future reference”.

Meanwhile, the Q-companion monitor displays the height and angle of your implement at any given time.

Controlling the implement position helps to find the right angle at the first attempt, it says, thus reducing the need for corrections. Reference positions can be stored for each implement, making the next job “even more efficient”.

Displaying the current and remaining lifting capacity using the same view is another benefit of the system, says Alo AB. This helps the operator to “avoid overloading the loader”.

The status monitor also allows for “more convenient and ergonomic loader work”, with “less risk of work-related injuries and fatigue”.

Q-Companion is also equipped with two individual maintenance indicators, which inform the operator of when to lubricate and when to tighten the sub-frame bolts. The maintenance reminder uses true working hours, rather than tractor clock hours, to ensure reminders happen when they are needed, says the company.