I had the opportunity of visiting two robotic dairy units of late, where the difference in milking speeds has been stark, to say the least.

For the record, the same type of robot was operating on both farms.

In one of the units, an average milking speed of 2.9L of milk per minute is being achieved; on the other, the equivalent figure was 1.9L.

By my calculations, this works out at around a 30% differential in the volumes of milk being harvested across the two farms.

In any man’s language, this is a more than significant figure.

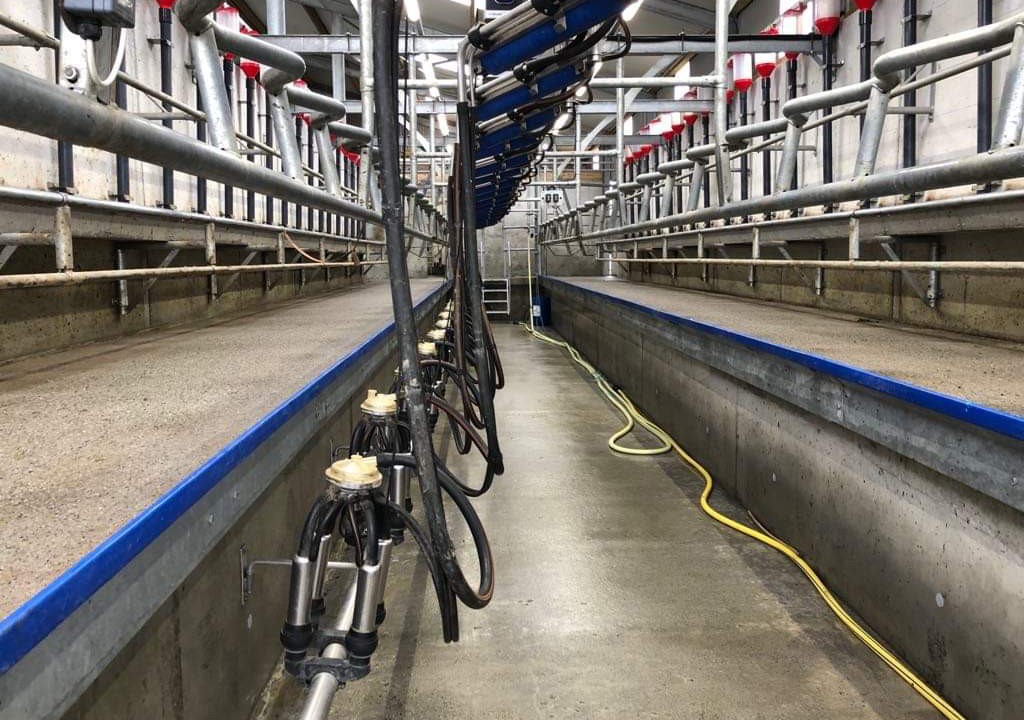

Robotic milking

The cows on both of the farms had excellent breeding profiles, but as many dairy farmers will testify, some cows are just slower milkers than others.

The cows in question have lots of time to express their milk as the system completes its full 360° rotation.

On the odd occasion, where a cow takes that little bit longer to fully express her milk, she can be kept on for a second spin around – without holding up the entire milking schedule.

Where a robotic scenario is concerned, one or two slow-milking animals can really hold up proceedings. The end result here is a significant drop-off in the milk output secured over the course of a day, a week or a year.

Milking robots are not cheap pieces of kit to purchase, so making best use of the technology is an absolute necessity.

Milking speed

A brief glance at some current dairy sire catalogues would point to a wide difference in the projected milking speeds of the daughters the different bulls will produce.

The real question is this – is it possible to breed for enhanced milking speed while still securing improved production and milk components?

It is not unrealistic for dairy farmers to want the bulls they use to tick every box. Robotic milking looks set to become even more prevalent within the Irish dairy sector over the coming years.

With farmers finding it as difficult as it ever has been to get ‘good staff’, utilising robotic milking systems seems to be an obvious choice.