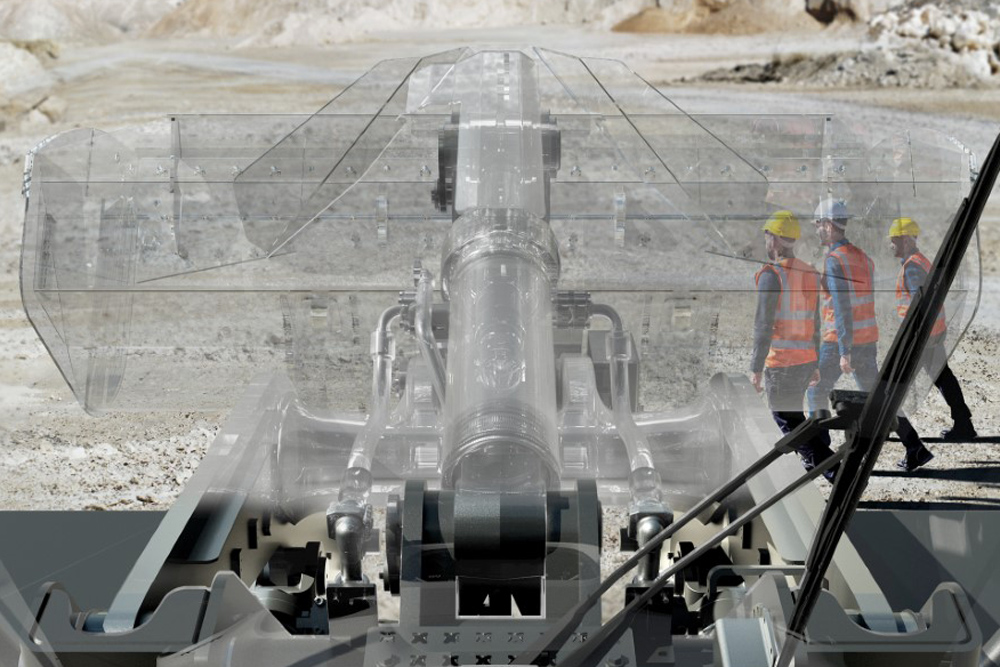

Doosan combines twin camera feeds

The feeds from the two cameras are then merged to form a single image on an in-cab screen, using a curved projection method. This not only adds greatly to safety, but also to efficient operation.

Biggers buckets lead to bigger blind spots

The idea for the system arose as videos of accidents caused by the lack of visibility become more widespread on the internet.

As machinery and site safety standards continue to be significantly raised around the world, advanced safety systems have become a key factor in selecting equipment. We plan to continue developing safety features that can protect drivers and other workers on site.”AVM is based on ultrasonics whereas the 'Transparent Bucket' concept works with visual light. Although this is obviously a great step forward from a safety angle, it remains to be seen how it might cope with dusty conditions. The 'Transparent Bucket' will be available on loaders from later this year.